One of the final stages when the glass is in and the solder joins are done is either puttying or cementing. As this panel has a mixture of lead and copper foil putty seemed the best option for it (you can be a bit gentler and put the putty exactly where you need it as opposed to covering the piece in cement & being quite rough). I opened up the lead with my oyster knife and after combining the putty with some blackit it was rolled into a sausage & squeezed into the gaps (the putty’s job is to fill the gaps & stop the glass rattling around within the lead). After letting the putty dry for a couple of days I went round the inside of the lead with a matchstick and then with a horseshoe nail a couple of days after that (to get sharp edges). The difference is very noticeable – before

One of the final stages when the glass is in and the solder joins are done is either puttying or cementing. As this panel has a mixture of lead and copper foil putty seemed the best option for it (you can be a bit gentler and put the putty exactly where you need it as opposed to covering the piece in cement & being quite rough). I opened up the lead with my oyster knife and after combining the putty with some blackit it was rolled into a sausage & squeezed into the gaps (the putty’s job is to fill the gaps & stop the glass rattling around within the lead). After letting the putty dry for a couple of days I went round the inside of the lead with a matchstick and then with a horseshoe nail a couple of days after that (to get sharp edges). The difference is very noticeable – before

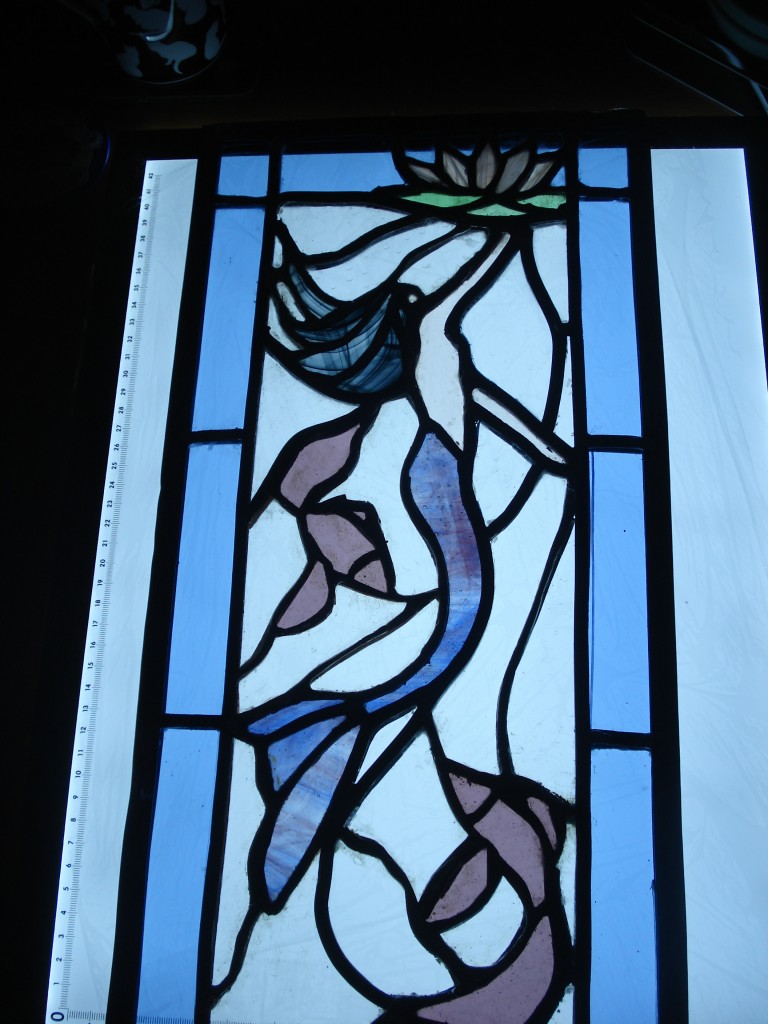

After

The final stage is to darken the lead with polish and rub the whole thing with car wax to protect the lead and glass. Onto the next panel!